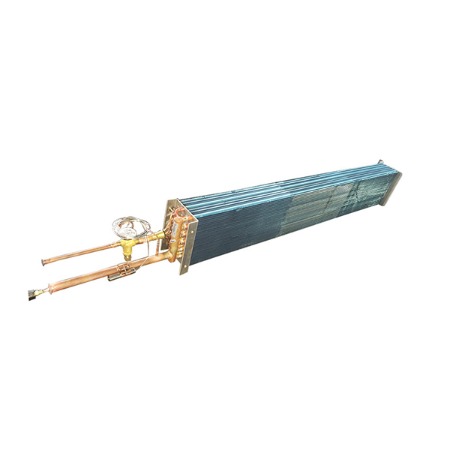

Fin tube heat exchangers are used in many applications such as air conditioning and car radiators. They increase the surface area of the tubes and this increases the overall heat transfer rate.When designing a finned tube heat exchanger, you need to calculate the required heat transfer area and optimum spacing of the tubes. This is achieved by running fluid flow calculations on a computer. This ensures that the correct tube design is used to maximize the desired rate of heat transfer.

The most common type of heat exchanger is the plate and fin heat exchanger (PFHE). This is used for transferring heat between gas and liquids, although it can also be applied to two-phase liquids.This type of heat exchanger uses alternating layers of corrugated metal plates and fins to separate the two streams. The plates and fins are fabricated from aluminum, stainless steel or copper.

Plate and fin heat exchangers are a great alternative to shell and tube heat exchangers for applications where metal has low thermal conductivity. They also have a very large heat transfer area per volume and are typically very compact and light weight.In addition, they are able to handle much higher working pressures than shell and tube types. This makes them ideal for deep-low temperature equipment, such as oxygen production and ethylene and helium liquefaction.

Another popular type of heat exchanger is the wire loop heat exchanger. These tubes have a series of elongated wire loops that enhance the secondary surface and are soft-soldered to the tube wall. This type of tube has excellent heat transfer characteristics because it can promote turbulence in the fluid.

English

English 中文简体

中文简体